Monitor VESA Mounting Plate

- Steel plate mount for attaching monitors to Flexpipe structures

- Compatible with 75x75 mm and 100x100 mm VESA hole patterns

- Designed to integrate easily with 28 mm pipe systems

- Ideal for ergonomic workstations and industrial computer stations

The AW-MOUNT is a versatile monitor mounting plate designed to integrate seamlessly with Flexpipe’s modular pipe and joint system. Built from robust steel, this plate offers secure attachment for flat-screen monitors on lean workstations, mobile carts, and inspection setups.

VESA Compatibility

This monitor mount supports the two most common VESA standard patterns:

- 75 x 75 mm

- 100 x 100 mm

These hole patterns allow for easy mounting of a wide range of monitors typically used in industrial and shop floor environments.

Modular Integration

The plate is drilled and designed to be bolted directly onto a frame built with 28 mm Flexpipe steel pipes and joints. It can be positioned at any height or angle using compatible brackets, giving operators ergonomic flexibility.

Use Cases

Perfect for:

- Custom-built lean workstations with integrated digital tools

- Mobile assembly carts with barcode scanning or quality control stations

- Visual management boards with digital display panels

Installation

Can be installed using basic hardware and an Allen key – no welding or special tools required. Combine it with Flexpipe mounting brackets or adjustable arms for custom tilt or swivel capability.

| Box Quantity | 1 |

|---|---|

| Length | 4 7/8 in (123.8 mm) |

| Height | 4 7/8 in (123.8 mm) |

| Width | 1/16 in (1.6 mm) |

| Weight (kg/lbs) | 0.892 lb (0.405 kg) |

| Common Usage | Computer monitors and TV for workstation |

| Compatible brand | Creform, Fastube, Trilogiq (28 mm), NIS (28 mm), C Tek Lean Solutions (28 mm) |

| Non Compatible Brand | Trilogiq (28.6 mm) |

| Primary Material | Hot rolled steel (SPHC) with black cathodic electrodeposition (Ecoating) |

| Electric Conductivity (ESD) | No |

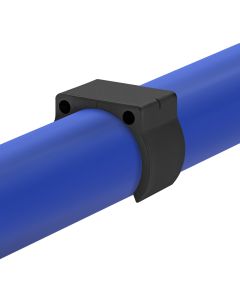

1. Screw the plate to the screen

2. Position the plate where you want it on the pipe

3. Position the H-15 and tighten it in the desired position

English US

English US  English CA

English CA  Français CA

Français CA  Español US

Español US