SKU

W-4PF

4" Rigid Plate Caster

- 4 inches (100 mm) diameter wheel

- 250 pounds (113 kg) loading capacity

- 2.5Mph maximum speed

CDN$12.31

Farnham:

1299

1299 units in stock

Location details

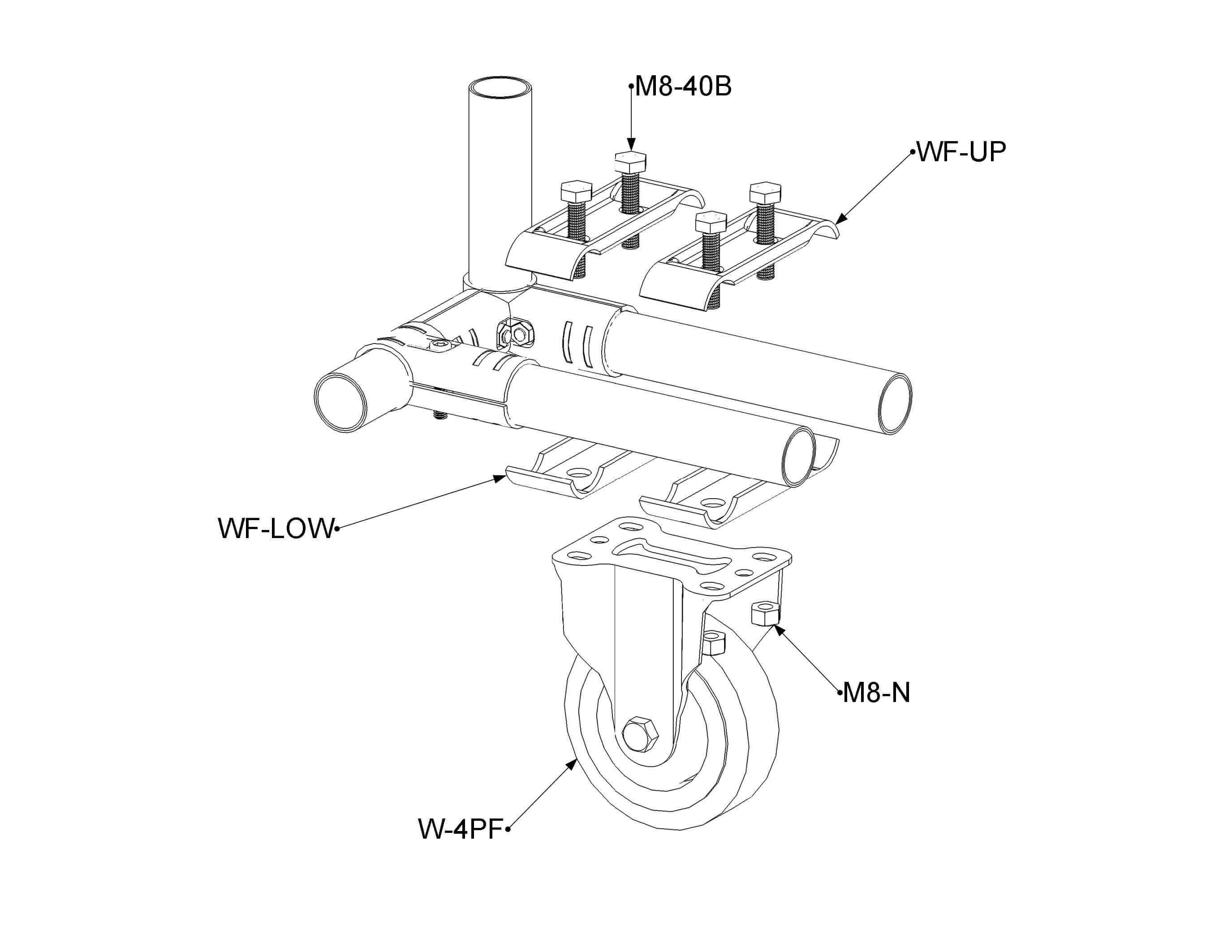

4 inches rigid plate caster with a loading capacity of 285 pounds (68 kg) and a maximum speed of 2.5Mph. Ensure you have two WF-UP, two WF-LOW, four M8-35B, and four M8-N to fix the caster on your structure. See the Installation Steps tab for more information on how to install W-4PF casters.

4 inches casters are made for:

- Longer trips (100 feet maximum)

- Higher frequency trips (100 to 150 times a day)

- Carts weighting more than 400 pounds

- Larger carts (greater than 24 in. wide and 48 in. long)

For heavy duty uses, we recommend considering the W-6PF caster.

All casters are equipped with a precision ball bearing.

For carts that will go outside, roll on ramps or damaged floors, it's preferable to use 6 inches casters.

| Box Quantity | 40 |

|---|---|

| Height | 5 1/8 in (130 mm) |

| Weight | 1.08 lb (0.49 kg) |

| Box Dimensions | Cardboard box of 18 X 11 X 12 in (460 X 280 X 300 mm) |

| Primary Material | Thermoplastic Rubber (TPR) |

| Temperature Resistance | -22°F to 158°F (-30°C to 70°C) |

| Electric Conductivity (ESD) | No |

| Loading Capacity | 250 lb (113 kg) |

- Ensure you have the following parts:

- 1x W-4PF

- 2x WF-UP

- 2x WF-LOW

- 4x M8-35B

- 4x M8-N

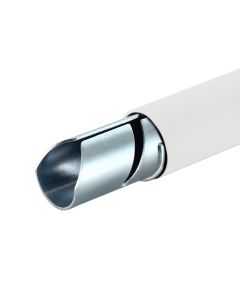

- 2x 28mm pipes of your choice

- 1x Wrench

- 1x Ratchet

- Ensure that the structure is leveled when supported by the pipes that will be wheeled. Otherwise, the height difference might cause the structure to sway.

- Flip the structure for better access to the bottom pipes.

- Ensure the pipes are parallel and have 3 1/4 in of center spacing.

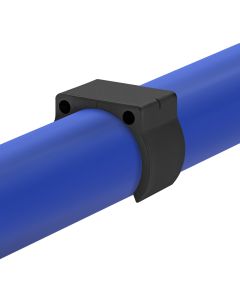

- Place the two WF-LOW perpendicular on the pipes.

- Place the caster on both WF-LOW and align the openings.

- Take one WF-UP and regroup it with one of the WF-LOW.

- Take two M8-35B bolts and two M8-N nuts and insert them into the corresponding openings. Then lightly tighten them together.

- Repeat steps 6 and 7 for the other WF-UP and the bolts and the nuts remaining.

- Tighten completely the four M8-35B bolts and the four M8-N nuts in a cross pattern.

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US