Tee Joint Set Steel

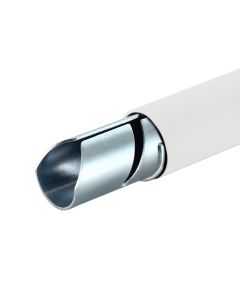

- Compatible with 28 mm pipes

-

Nuts and bolts are included, but packaged separately

-

Assembly is required

In stock

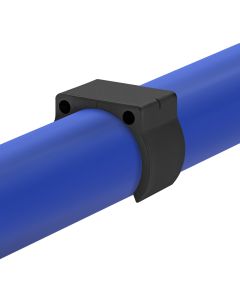

The HJ-1 is a black metal joint set that allows you to connect two 28 mm pipes in a T-shape or to create a corner. You can rotate this connector up to 360-degree before fixing it to make 45- or 90-degree support for surfaces or just for supporting your products.

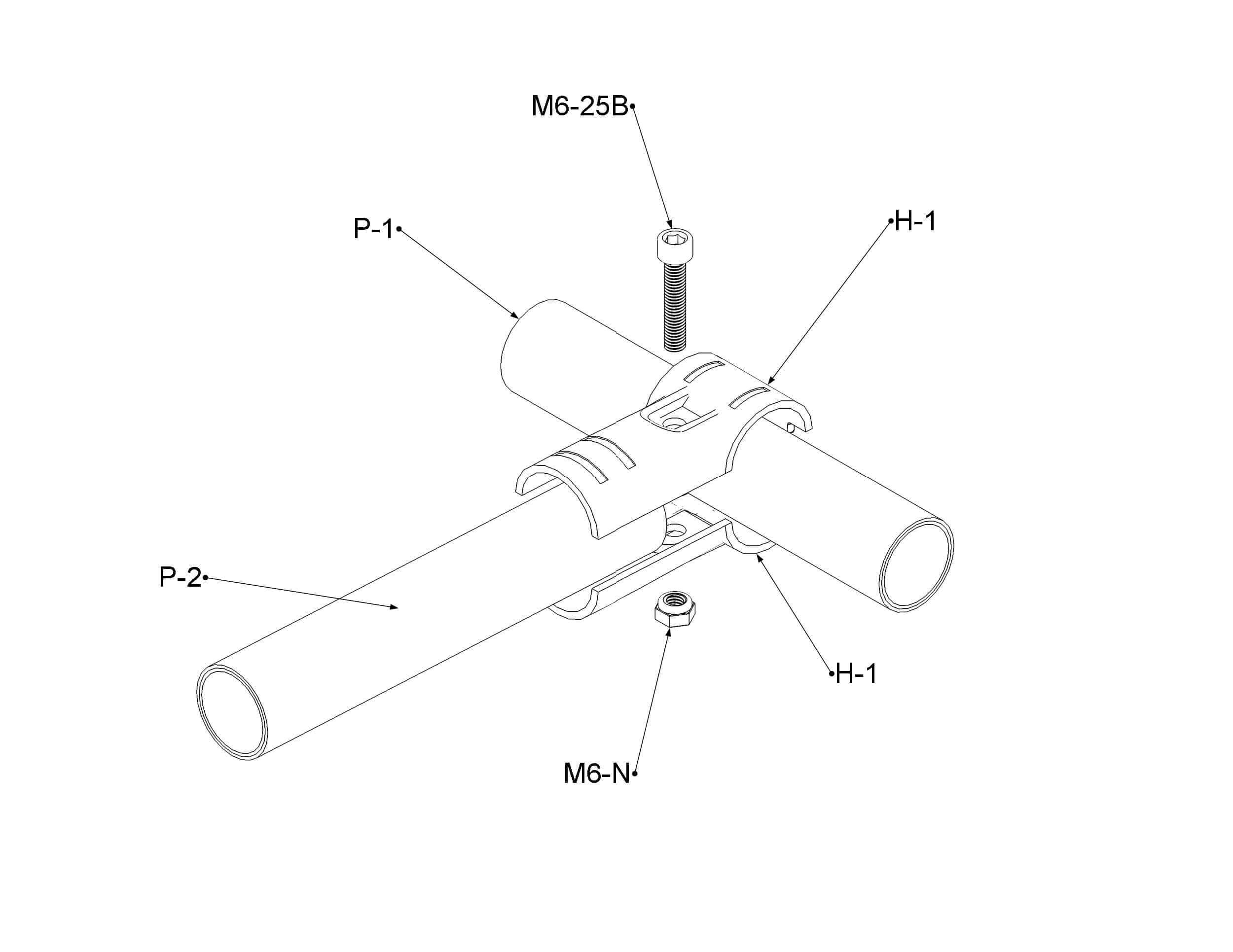

This connector was designed for a quick and easy installation. This piece is the simplest to assemble and the most commonly used in the entire Flexpipe system. Applications for this connector are numerous; from corners to separations, pegs, 45-degree supports and supports for accessories like the AW-HOLDER. To assemble an HJ-1 you need to put two H-1 together with an M6-25B bolt and an M6-N nut. You should always keep a box of these three parts in inventory since they are going to be used in 95% of your Flexpipe structures.

Technical Information:

This joint set is designed with 8 striations for a better grip on the plastic coating of the 28 mm pipes. It also includes 4 additional pre-drilled reinforcement holes to ensure extra strength to your structure. By adding a self-drilling screw F-A858, you will solidify the connector joints positioned on a corner where there is a higher risk of impact.

Installation Steps

See the installation steps tab to view how to assemble this connector.

Antistatic Version (ESD):

An electric conductivity version if offered if you wish to build antistatic structures: HJ-1NP

Want to reuse parts of your old system?

The HJ-1 Flexpipe joint set is compatible with many other pipe and connector systems. Check the technical information tab to know which systems are compatible and none-compatible with our parts.

Please note that nuts and bolts are included, but packaged separately. Assembly is required.

| Length | 3 1/4 in (83 mm) |

|---|---|

| Height | 1 5/16 in (33 mm) |

| Width | 1 5/16 in (33 mm) |

| Material Thickness | 1/8 in (2.5 mm) |

| Weight | 0.315 lb (0.143 kg) |

| Compatible brand | Creform, NIS, C Tek Lean Solutions, Trilogiq (28 mm) |

| Non Compatible Brand | Fastube, Trilogiq (28.6 mm) |

| Primary Material | Hot rolled steel (SPHC) with black cathodic electrodeposition (Ecoating) |

| Temperature Resistance | -148°F to 572°F (-100°C to 300°C) |

| Frequency of Use | Very high |

| Electric Conductivity (ESD) | No |

| Manufacturing Technique | Stamping and deburring |

- Ensure you have the following parts:

- Put the two H-1 together around the first pipe.

- Loosely tighten the bolt and the nut by putting them in the corresponding opening of the HJ-1.

- Insert the second pipe between the two H-1 at the opposite side of the joint, between the first and second guidelines.

- Tighten completely the M6-25B and the M6-N together until the HJ-1 is firmly attached to the pipes.

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US