Extend Pivot Joint Set Steel

- Adjustable from 15 degrees up to 260 degrees

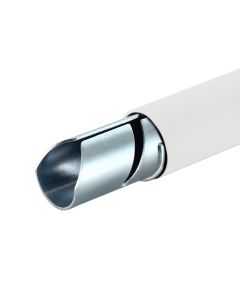

- Compatible with 28 mm pipes

- Nuts and bolts are included, but packaged separately

- Assembly required

In stock

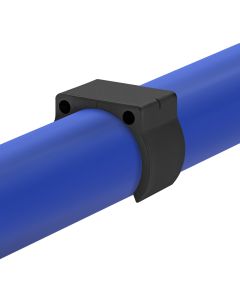

The HJ-6A is a black metal joint set that allows you to create a two-pipe intersection with an adjustable angle up to 260 degrees. This joint set allows working with a wider angle radius than the HJ-6 allows. It can be used for many applications such as the creation of angular sides and top or V-shaped racks with angles wider than 90 degrees. The distance created between the two pipes is used for supporting pannels or manufacturing parts.

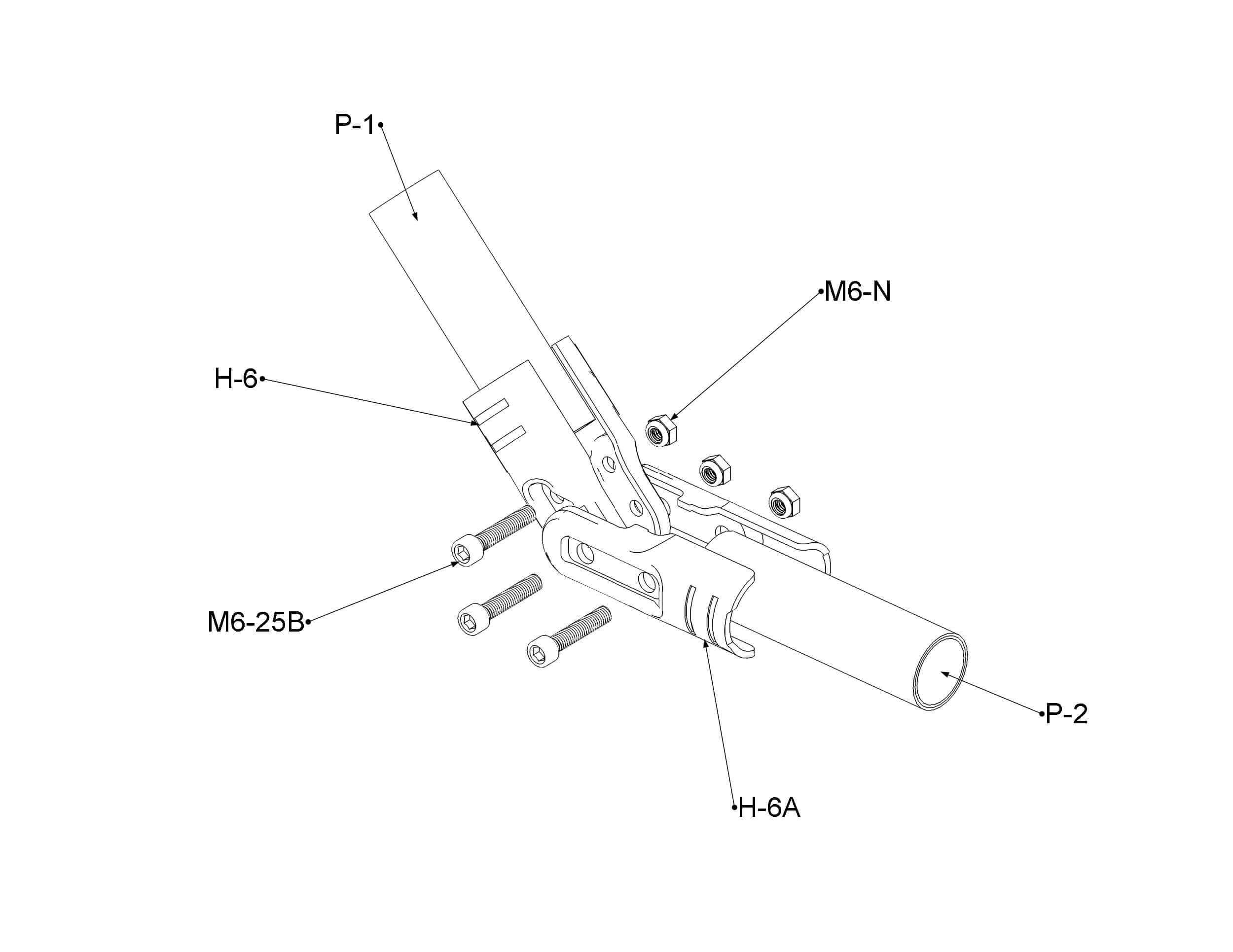

To assemble an HJ-6A you need to combine two H-6A and two H-6 together with three M6-25B bolts and three M6-N nuts.

Installation Steps:

See the installation steps tab to view how to assemble this connector.

Antistatic Version (ESD):

An electric conductivity version if offered if you wish to build antistatic structures: HJ-6ANP

Want to reuse parts of your old system?

The HJ-6A Flexpipe joint set is compatible with many other pipe and connector systems. Check the technical information tab to know which systems are compatible and none-compatible with our parts.

Please note that nuts and bolts are included, but packaged separately. Assembly is required.

| Length | 5 7/16 in (138 mm) |

|---|---|

| Height | 1 5/16 in (33 mm) |

| Width | 1 5/16 in (33 mm) |

| Material Thickness | 1/8 in (2.5 mm) |

| Weight | 0.609 lb (0.277 kg) |

| Compatible brand | Creform, NIS, C Tek Lean Solutions, Trilogiq (28 mm) |

| Non Compatible Brand | Fastube, Trilogiq (28.6 mm) |

| Primary Material | Hot rolled steel (SPHC) |

| Temperature Resistance | -148°F to 572°F (-100°C to 300°C) |

| Electric Conductivity (ESD) | No |

| Manufacturing Technique | Stamping and deburring |

- Ensure you have the following parts:

- Take the two H-6 connectors and group them around the first pipe.

- Fix the connectors by placing an M6-25B with an M6-N in the corresponding openings until it's firmly attached to the pipe.

- Group together with the two H-6A connectors around the second pipe and fix the connectors with an M6-25B and an M6-N in the corresponding openings until it's firmly attached to the second pipe.

- Insert the first pipe with the attached H-6 connectors in between the H-6A connectors and loosely tighten with the remainings M6-25B and the M6-N to both H-6 and H-6A connectors through corresponding openings.

- Position into the desired angle and tighten completely until the HJ-6A joint set is firmly attached to the first and the second pipe.

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US