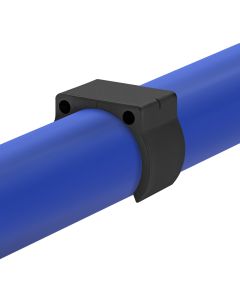

R85 Roller Track Mounting Bracket Start

- ESD-safe steel zinc conveyor mount

- Anchors roller tracks to perpendicular pipes

- Ideal for L-shape and Z-shape flow racks

- Compatible with 1 1/16 in (28 mm) pipe systems

The R85-MS is an electrostatic discharge (ESD) compliant steel mounting bracket designed to secure R85 roller tracks to perpendicular pipes. Commonly used at the starting point of a conveyor, it's also ideal for constructing L-shape and Z-shape flow racks, ensuring stable and reliable track anchoring.

Key Features

- Secure Anchoring – Built-in grip bumps provide firm contact with the pipe, preventing slippage and maintaining alignment.

- ESD Compliance – Made from ESD-safe steel, ideal for transporting sensitive electronic components.

- Easy Installation – Installs easily with an F-A85/8 screw, allowing for quick and secure fastening.

- System Compatibility – Designed to fit the R85-RT96 and other 1 1/16 in (28 mm) pipe and joint systems.

- Ideal for Custom Flow Racks – Frequently used in modular designs like L- and Z-shaped racks for better layout flexibility.

Integrating the R85-MS into your modular structures enhances the efficiency of lean manufacturing systems, including flowracks and lean warehouse setups. Flexpipe’s modular solutions serve industries such as warehousing, aerospace, and corrugated packaging. For added customization, take advantage of our cutting service and assembly service.

Need help getting started? Visit our guide on building modular flow racks for ideas and instructions.

| Box Quantity | 15 |

|---|---|

| Length | 3 1/18 in (78 mm) |

| Height | 1 5/16 in (33 mm) |

| Width | 3 9/16 in (90.6 mm) |

| Weight | 0.462 lb (0.20 kg) |

| Non Compatible Brand | Trilogiq |

| Primary Material | Galvanised hot rolled steel (SPHC) |

| Temperature Resistance | -148°F to 428°F (-100°C to 220°C) |

| Electric Conductivity (ESD) | Yes |

| Manufacturing Technique | Pressed and deburring |

- Ensure you have the following parts:

- 1x R85-MS

- 1x F-A858

- 1x 28mm pipe

- 1x R85-RT96

- 1x Drill

- Insert the R85-RT96 inside the R85-MS.

- Hang the R85-MS on the pipe perpendicularly.

- Screw a F-A858 in the corresponding opening through the pipe to fix the R40-MS mount.

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US