Cross Hinge Joint Set Steel

- Great for sliding or swiveling mechanisms

- Great for doors and drop-down extensions

- Great for adjustable mechanisms

- Nuts and bolts are included, but packaged separately

- Assembly is required

In stock

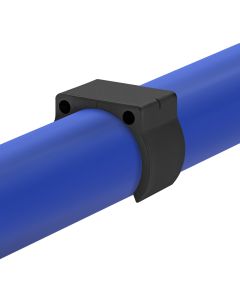

The HJ-24 is a black metal joint set that allows you to create a swivel three-pipe intersection on two axes.

To assemble an HJ-24 you need to combine two H-24, an AP-HINGE hinge bracket, two M6-25B bolts and two M6-N nuts.

Technical Information:

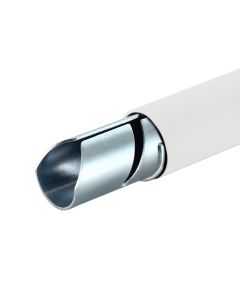

This joint set is designed with 8 striations for a better grip on the plastic coating of the 28 mm pipes.

Assembly tip:

If your structure doesn't require a swivel joint, we recommend that you use the HJ-4, because it will not weaken your structure's capacity. This joint set is very similar to the HJ-24 with the only difference that is doesn't have a hinge bracket.

Installation Steps:

See the installation steps tab to view how to assemble this connector.

Antistatic Version (ESD):

An electric conductivity version if offered if you wish to build antistatic structures: HJ-24NP

Want to reuse parts of your old system?

The HJ-24 Flexpipe joint set is compatible with many other pipe and connector systems. Check the technical information tab to know which systems are compatible and none-compatible with our parts.

Please note that nuts and bolts are included, but packaged separately. Assembly is required.

| Length | 5 1/8 in (130 mm) |

|---|---|

| Height | 1 5/16 in (33 mm) |

| Width | 1 5/16 in (33 mm) |

| Material Thickness | 1/8 in (2.5 mm) |

| Weight | 0.502 lb (0.228 kg) |

| Compatible brand | Creform, Fastube, Trilogiq (28 mm), NIS (28 mm), C Tek Lean Solutions (28 mm) |

| Non Compatible Brand | Trilogiq (28.6 mm) |

| Primary Material | Hot rolled steel (SPHC) with black cathodic electrodeposition (Ecoating) |

| Secondary Material | Polyethylene (PE) |

| Temperature Resistance | -148°F to 572°F (-100°C to 300°C) |

| Frequency of Use | Very low |

| Electric Conductivity (ESD) | No |

| Manufacturing Technique | Stamping and deburring |

- Ensure you have the following parts:

- Press the AP-HINGE bracket on the first pipe until it clips on, place the opening of the bracket inside of the pipe.

- Group the two H-24 connectors around the first and the second pipe. Make sure that the AP-HINGE bracket teeth fit into the corresponding openings.

- Fix the connectors together by placing the bolts with the nuts in the corresponding openings, and loosely tighten. Make sure to place the bolts on the most accessible side.

- Insert the second and the third pipes in both of the remaining openings of the HJ-24, between the first and the second positioning guidelines.

- Tighten completely until the HJ-24 joint set is firmly attached to the three pipes.

- If the HJ-24 feels too tight to rotate, apply a lubricant spray to ease the mobility of the AP-HINGE bracket and to avoid damaging the plastic teeth.

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US