SKU

R40-MS

R40 Roller Track Mounting Bracket Start

- ESD Protection – Ensures electrostatic discharge safety.

- Durable Zinc-Coated Steel – Resists corrosion for longevity.

- Secure Installation – Features bumps for firm pipe grip.

- Universal Compatibility – Fits 28mm (1 1/16 in) pipe systems.

CDN$2.10

Farnham:

7068

7068 units in stock

Location details

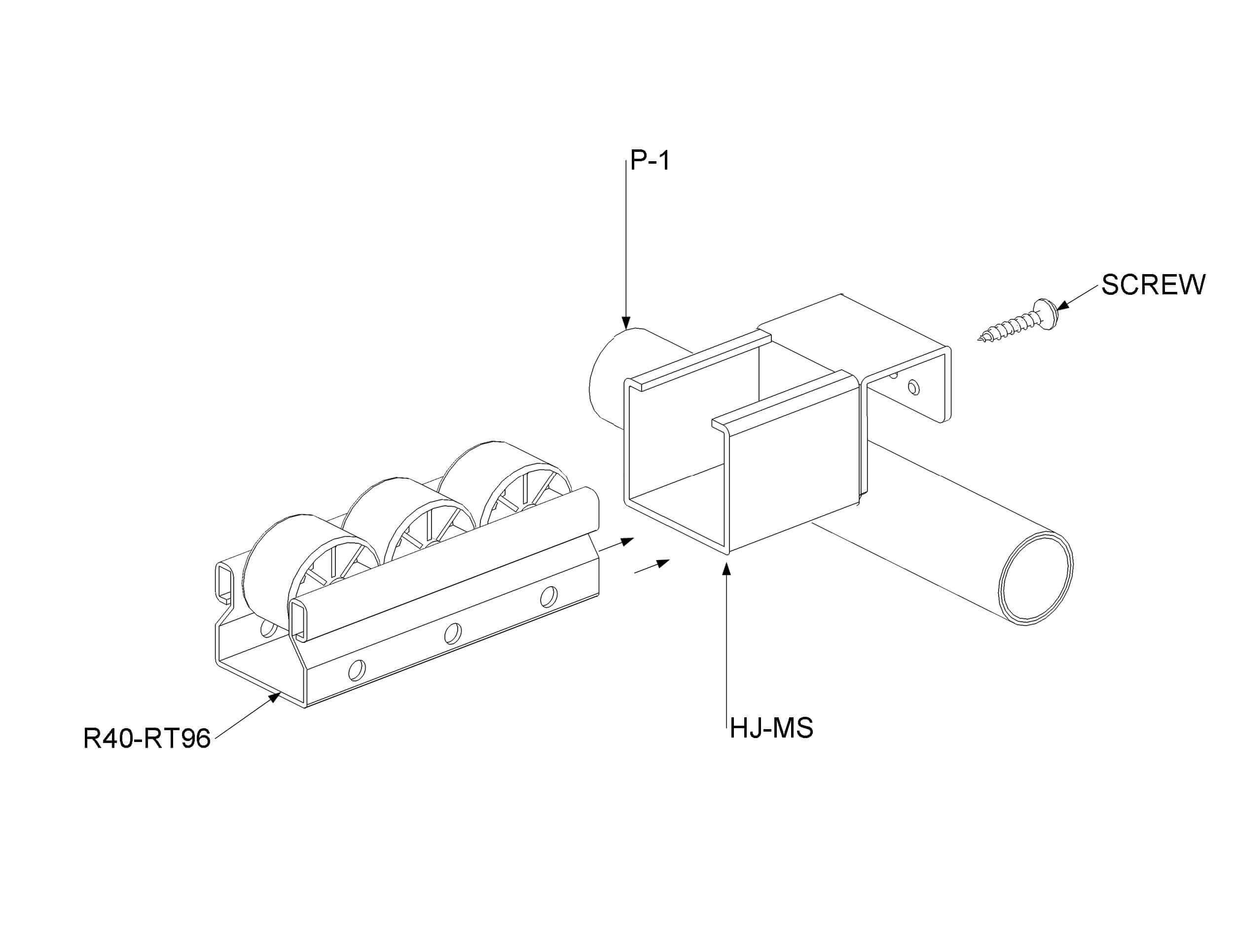

The R40-MS is a zinc-coated steel mounting bracket designed to initiate roller tracks in modular pipe systems. Ideal for industries requiring efficient material flow, it ensures electrostatic discharge (ESD) protection, making it suitable for environments handling electronic components.

Key Features

- Electrostatic Discharge (ESD) Protection – Prevents static buildup, safeguarding sensitive electronic components.

- Durable Zinc-Coated Steel Construction – Offers corrosion resistance, ensuring long-term structural integrity.

- Enhanced Stability – Integrated bumps on the anchoring section provide a firm grip on pipes, reducing slippage.

- Easy Installation – Designed for straightforward setup; securing with an F-A858 screw is recommended.

- Wide Compatibility – Compatible with 28mm (1 1/16 in) pipe and joint systems, facilitating integration into existing setups.

Recommended Products

- R40-RT96 Roller Track – Pairs seamlessly with the R40-MS for smooth material flow.

- F-A858 Screw – Ensures secure attachment of the R40-MS to pipes.

- R40-TS Mount Bracket with Tab Stop – Provides controlled stopping points in flow racks.

Additional Resources

- How to Build Modular Flow Racks – A comprehensive guide to designing efficient flow racks.

- Flow Rack Starter Kit – An all-in-one solution for initiating modular flow systems.

Leveraging Flexpipe's expertise in lean manufacturing solutions, the R40-MS enhances operational efficiency by facilitating seamless material handling. Its robust design and compatibility with standard pipe systems make it an essential component for creating customized flow racks and workstations.

| Box Quantity | 30 |

|---|---|

| Length | 3 1/16 in (78 mm) |

| Height | 1 5/8 in (41 mm) |

| Width | 0.34 lb (0.154 kg) |

| Weight | 0.341 lb (0.155 kg) |

| Non Compatible Brand | Trilogiq |

| Primary Material | Galvanised hot rolled steel (SPHC) |

| Temperature Resistance | -148°F to 428°F (-100°C to 220°C) |

| Electric Conductivity (ESD) | Yes |

| Manufacturing Technique | Pressed and deburring |

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US