Motor Driven 12" Lift Kit with Caster - 1320 lb

- The system is operated by means of an internal spindle drive driven by an electric motor. The maximum loading capacity is 1320lb (598 kgs) and the adjustment range is up to 11.8'' (300 mm).

- Using the lift kit you can retrofit your work table that previously could not be adjusted in height with just a few steps, thus making it height-adjustable. This "Bolt-On" lift system is easy to install.

- OCT. 2021 PRODUCT UPDATE: Parts added to fix the legs on the pipes and the crank on a surface.

- Kit includes 4 foot levelers and 4 4 inches swivels casters with brake

Out of stock

The Bolt-On system is delivered as a kit for retrofitting. You can retrofit your work table that previously could not be adjusted in height with just a few steps, thus making it height-adjustable. System includes:

- Control box, and manual control switch

- Four "Bolt-On" lift columns

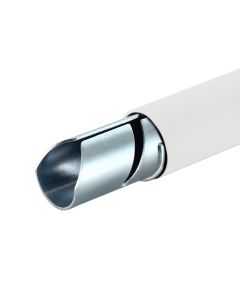

- Four 3 m (9 ft.) sections of flexible tubing

- Four glides

- Four foot levelers

- Four 4 Inches swivels casters with brake W-4ESBLK

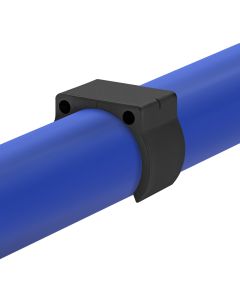

- Drilling templates, tubing clips, and cable ties

- Installation and operating instructions

They are ideally suited for cleanroom applications in medical technology, aerospace, biomedical and electronics manufacturing. Passed the Cleanroom Class 3 according to ISO Class 14644-1.

The maximum loading capacity is 1320 lb (598 kg) and the adjustment range is up to 11.8" (300 mm).

Cables connected to the controller device (black box) are 78 inches (1.98 m) long. Poser supply cable is 9 feet (2.75 m) long.

Download here the complete manual and assembly instructions

Reset Weight

Spindle lifting system lifts and retracts load with the help of a motor. No restoring force is required.

Load distribution

The lifting systems are designed for loads that are unevenly distributed on the working surface. The maximum load on the working surface may not exceed the system's rated lifting capacity. The maximum load per cylinder may not exceed the rated lifting capacity divided by the number of cylinders x 1.5.

Work cycle

The lifting systems are designed for a work cycle of 10%. This means that nine minutes of resting time is provided per minute of operating time. These adjustable systems are not designed for continuous operation.

Operating temperature

Lifting systems work best at operating temperatures between 0°C and 40°C.

Tube length

Specific lengths are specified for all standard lifting systems (see the drawing by clicking on the main picture) Individual hose lengths can be ordered at the customer's request within the permissible range. A ratio of tube lengths of 1:3 should be maintained. (Minimum hose length 0.5 m - maximum hose length 5 m).

Bending radius

The hydraulic lines to connect the pump to the lifting cylinders are to be laid so that the bending radius of the hoses is not less than 50 mm.

Durability test

The lifting systems are tested regularly to ensure the flawless functioning of the system over at least 10,000 complete up / down cycles.

Download here the complete manual and assembly instructions

Contact your regional sales manager for volume pricing.

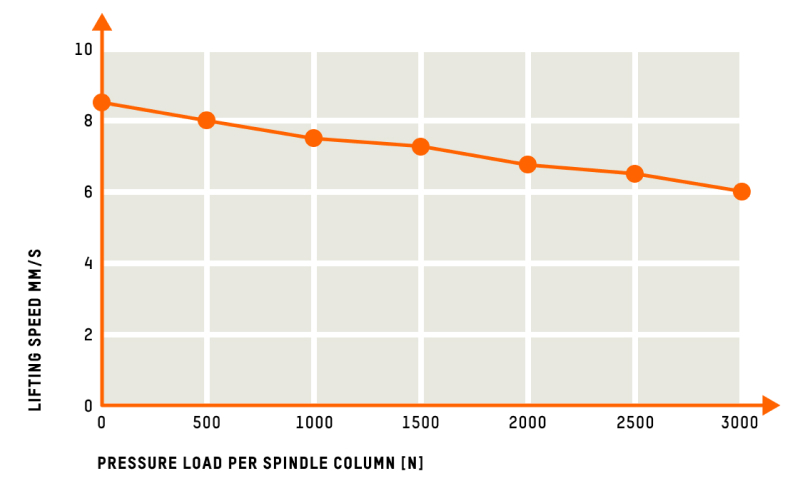

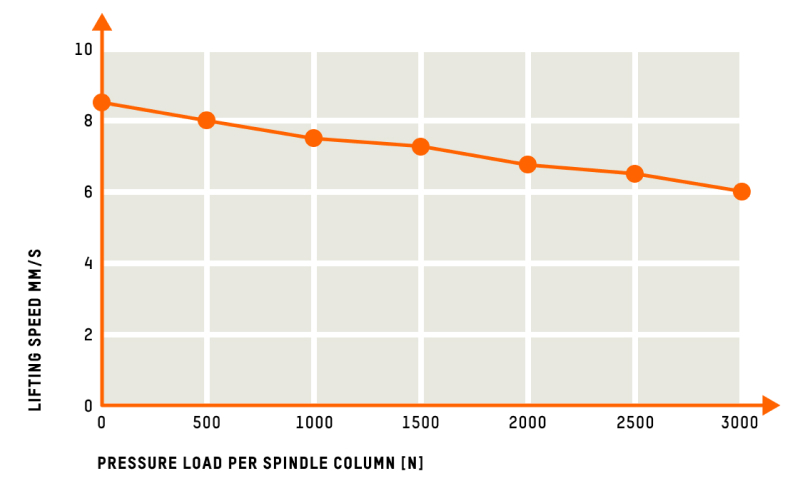

Height adjustment speed

| Box Quantity | 1 |

|---|---|

| Weight | 35 lb (15.9 kg) |

| Box Dimensions | Cardboard box of 47 X 14 X 10 in (1194 X 356 X 254 mm) |

| Common Usage | Adjustable work bench or adjustable flow racks |

| Primary Material | Aluminum |

| Temperature Resistance | 32°F to 104°F (0 °C to 40 °C) |

| Frequency of Use | Medium |

| Electric Conductivity (ESD) | No |

| Loading Capacity | 1000 lb (454 kg) |

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US