5s Kaizen Foam 13 layers 2.4" x 20" x 40"

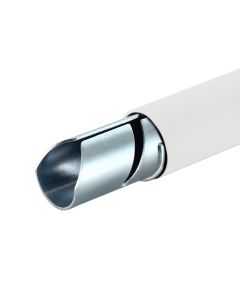

- 13 layers black and red sandwiched foam sheet

- 19.5in x 39.5in x 2.4in

- Easy to cut thanks to the different layers to easily reach the necessary depth

- Perfect to build 5S shadow boards for maximum organization and visual control

Use this kaizen foam to build 5S shadow boards as the ultimate solution for organization, ensuring that your tools are always in the right place when you need them.

Made from high-quality polyethylene foam, this multi layer foam sheet is both durable and lightweight. Its unique structure allows you to easily customize it to fit any size or shape of tool or equipment, making it the perfect solution for any workspace.

Simply trace the outline of your tools onto the foam, then use a sharp knife or blade to cut out the shape. The result is a perfectly fitted slot that securely holds your tools in place, preventing them from shifting or getting lost.

Its bright, contrasting black and red colors make it easy to identify missing tools and ensure that everything is in its proper place.

Say goodbye to cluttered workspaces and lost tools - with custom 5S shadow boards, everything has its place!

| Length | 39 3/8 in (1000.125 mm) |

|---|---|

| Height | 2 1/4 in (57.15 mm) |

| Width | 19 11/16 in (500.062 mm) |

| Weight | 2.2 lb (1 kg) |

| Common Usage | Shadow boards for tool organization |

| Primary Material | Polyethylene |

| Temperature Resistance | -4°F to 158°F (-20°C to 70°C |

| Electric Conductivity (ESD) | No |

| FAQ | What is Kaizen foam?Kaizen foam is a versatile, multi-layered foam used primarily for organizational purposes, such as in toolboxes, storage cases, and workspaces. It helps in creating customized inserts that securely hold and protect tools or items, enhancing organization and efficiency. How to use Kaizen?To use Kaizen foam, measure the space or container you wish to line with the foam. Cut the foam to size, then lay out the tools or items on the foam, marking their outlines. Use a knife to cut along the outlines, creating a snug fit for each item. Remove the cut pieces to create custom-fitted slots. What do you use to cut Kaizen foam?A sharp utility knife or a scalpel is typically used to cut Kaizen foam. These tools allow for precision cuts and the ability to easily follow the traced outlines of tools or items. Can Shadow Foam be laser cut?Yes, Shadow Foam, a similar product to Kaizen foam, can be laser cut. Laser cutting allows for precise and clean cuts, making it a suitable method for creating complex or detailed inserts. How do you separate Kaizen foam layers?To separate Kaizen foam layers, you can use a knife or fingers to peel apart the layers at the desired depth. This method is useful for creating recessed spots or compartments for storing tools or items without cutting all the way through the foam. How do you smooth Kaizen foam?After cutting and removing pieces of Kaizen foam, smoothing can be achieved by gently using a fine-grit sandpaper over rough edges or by lightly heating the cut edges with a heat gun to soften and smooth them. Why it is called 5S Kaizen Foam?It is called 5S Kaizen Foam because it aligns with the 5S methodology of organization and efficiency, originating from Japan. The 5S stands for Sort, Set in order, Shine, Standardize, and Sustain, principles that Kaizen foam helps implement by organizing tools and workspaces effectively. What are the drawbacks of Kaizen?Drawbacks of Kaizen may include the initial time and effort required to design and cut out foam inserts, potential waste from cutting mistakes, and the foam's susceptibility to wear and tear or damage from oil and other chemicals over time. What is the best example of Kaizen Foam Utilization?A prime example of Kaizen Foam utilization is in tool organization within workshops or toolboxes. By custom-cutting foam inserts to fit each specific tool, users can quickly identify and access tools, notice missing items at a glance, and prevent damage from tools knocking together. This method significantly boosts efficiency and supports the principles of workplace organization and safety. |

What is Kaizen foam?

Kaizen foam is a versatile, multi-layered foam used primarily for organizational purposes, such as in toolboxes, storage cases, and workspaces. It helps in creating customized inserts that securely hold and protect tools or items, enhancing organization and efficiency.

How to use Kaizen?

To use Kaizen foam, measure the space or container you wish to line with the foam. Cut the foam to size, then lay out the tools or items on the foam, marking their outlines. Use a knife to cut along the outlines, creating a snug fit for each item. Remove the cut pieces to create custom-fitted slots.

What do you use to cut Kaizen foam?

A sharp utility knife or a scalpel is typically used to cut Kaizen foam. These tools allow for precision cuts and the ability to easily follow the traced outlines of tools or items.

Can Shadow Foam be laser cut?

Yes, Shadow Foam, a similar product to Kaizen foam, can be laser cut. Laser cutting allows for precise and clean cuts, making it a suitable method for creating complex or detailed inserts.

How do you separate Kaizen foam layers?

To separate Kaizen foam layers, you can use a knife or fingers to peel apart the layers at the desired depth. This method is useful for creating recessed spots or compartments for storing tools or items without cutting all the way through the foam.

How do you smooth Kaizen foam?

After cutting and removing pieces of Kaizen foam, smoothing can be achieved by gently using a fine-grit sandpaper over rough edges or by lightly heating the cut edges with a heat gun to soften and smooth them.

Why it is called 5S Kaizen Foam?

It is called 5S Kaizen Foam because it aligns with the 5S methodology of organization and efficiency, originating from Japan. The 5S stands for Sort, Set in order, Shine, Standardize, and Sustain, principles that Kaizen foam helps implement by organizing tools and workspaces effectively.

What are the drawbacks of Kaizen?

Drawbacks of Kaizen may include the initial time and effort required to design and cut out foam inserts, potential waste from cutting mistakes, and the foam's susceptibility to wear and tear or damage from oil and other chemicals over time.

What is the best example of Kaizen Foam Utilization?

A prime example of Kaizen Foam utilization is in tool organization within workshops or toolboxes. By custom-cutting foam inserts to fit each specific tool, users can quickly identify and access tools, notice missing items at a glance, and prevent damage from tools knocking together. This method significantly boosts efficiency and supports the principles of workplace organization and safety.

English CA

English CA  Français CA

Français CA  English US

English US  Español US

Español US