Bolt for joint sets

- Used to assemble 99% of all Flexpipe joints

- High corrosion resistance

- 1800 units per box (please order individually)

The M6-25B is a black coated metal bolt that is used to assemble 17 of the 18 different connectors in the Flexpipe system. This bolt and the M6-N nut are the foundation of every Flexpipe structure.

We highly recommend that you keep a box or two of M6-25B at all times, since you will use a lot of them for all your structures.

The M6-25B bolt was designed to assemble Flexpipe HJ joints, and it was created to do only that. We don't recommend that you use this part with the M6-N nut to connect anything other than the Flexpipe system.

Installation Steps:

See the installation steps tab to view how to assemble this bolt.

Technical Information:

This bolt is fixed to the M-6N using a 5mm T-HANDLE allen wrench.

(It is essential that the bolt is tightened between 12-14 N.m torque)

Antistatic Version (ESD):

Be sure to select the antistatic version M6-25BWZ for all the ESD connectors. This version is nickel-plated to provide the same ESD characteristics as the Nickel Plated joints.

Want to reuse parts of your old system?

The M6-25B Flexpipe is compatible with many other pipe and connector systems. Check the technical information tab to know which systems are compatible and none-compatible with our parts.

| Box Quantity | 1800 |

|---|---|

| Weight (kg/lbs) | 0.015 lb (0.007 kg) |

| Box Dimensions | Cardboard box of 11 X 9 X 5 in (279 mm X 229 mm X 127 mm) |

| Common Usage | Used to assemble 99% of all Flexpipe joints |

| Compatible brand | Flexpipe, Creform, Fastube |

| Non Compatible Brand | Trilogiq |

| Primary Material | SCM440 with black cathodic electrodeposition (Ecoating) |

| Temperature Resistance | -40°F to 572°F (-40°C to 300°C) |

| Frequency of Use | Very high |

| Electric Conductivity (ESD) | Yes |

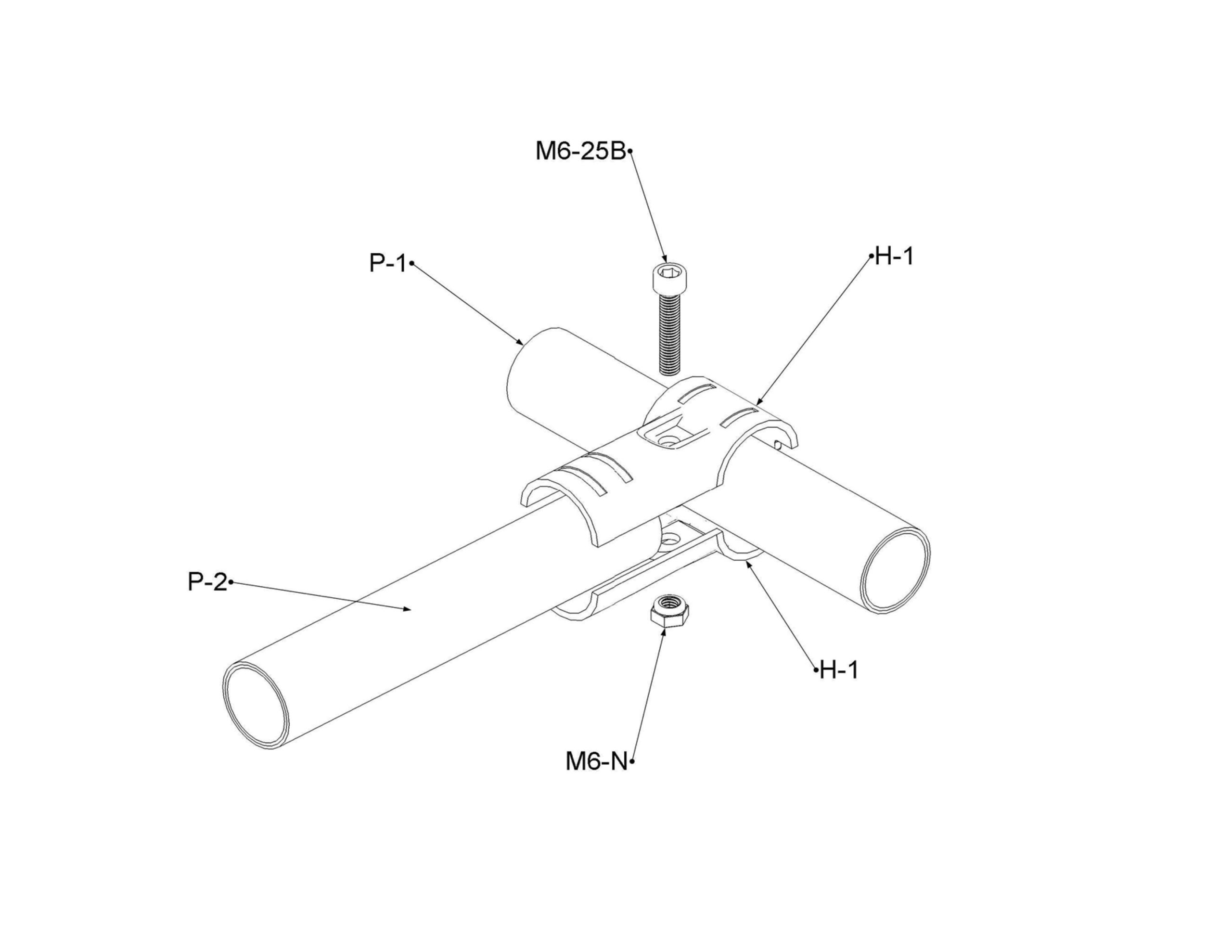

- Ensure you have the following parts:

- 1x Joint set of your choice

- (1-4)x M6-25B bolts (depending on Joint set)

- (1-4)x M6-N nuts (depending on Joint set)

- (2-5)x 28mm pipes of your choice (depending on Joint set)

- 1x T-HANDLE 5mm hex key

- Group connectors around corresponding pipes.

- Make sure to put the bolt on the most accessible side and insert the smaller diameter of the nut into the corresponding hole.

- Loosely tighten all M6-25B bolts and M6-N nuts by putting them in the corresponding openings of the particular joint set.(Press the nut into the connector using your finger tip and turn the bolt into the nut with other hand).

- Fully insert all pipes

- Tighten completely the M6-25B and the M6-N together until the Joint set is firmly attached to the pipes. A force between 12-14 Nm is recommended for this step.

You need to enter info before adding a new review.

Need more informations ?

Here's everything you need to know!

English US

English US English CA

English CA Français CA

Français CA Español US

Español US