4 way cross joint set steel black

In stock

- Compatible with 28 mm pipes

- Nuts and bolts are included, but packaged separately

- Assembly required

The HJ-3 is a black metal joint set that allows you to create a four-pipe intersection or a corner. This joint set is excellent for making corner pegs at 90 degrees. It is also often used in the center of structures to create strong counterweight and in the bottom of structures to fix stem-mount casters.

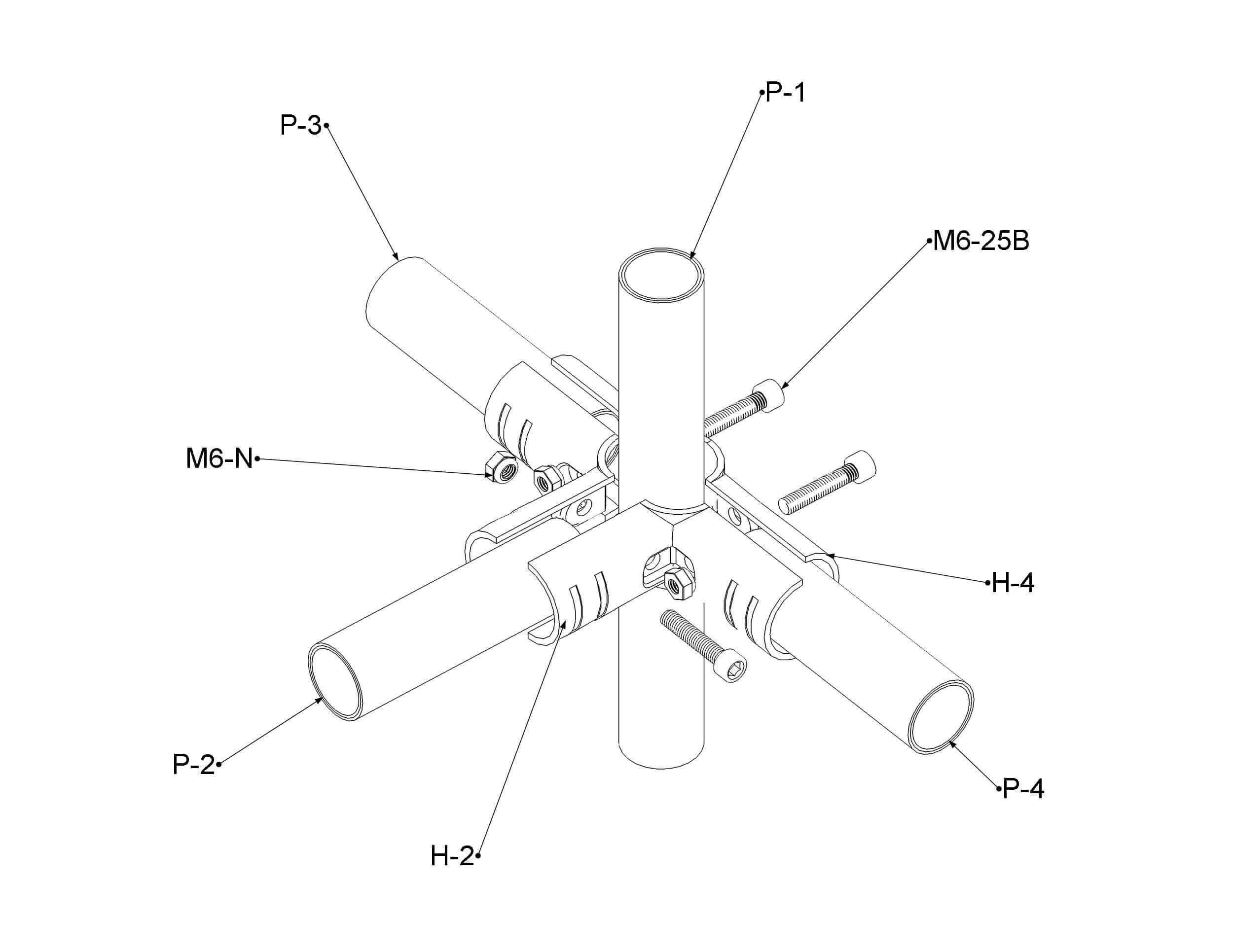

To assemble an HJ-3 you need to combine two H-2 and an H-4 together with three M6-25B bolts and three M6-N nuts. This connector is a little bit trickier to assemble than the HJ-1 or HJ-2, but when fixing both H-2 parts together first, you should have an installed HJ-3 connector in no time.

Technical Information:

This joint set is designed with 14 striations for a better grip on the plastic coating of the 28 mm pipes. It also includes 3 additional pre-drilled reinforcement holes to ensure extra strength to your structure. By adding a self-drilling screw F-A85/8, you will solidify the connector joints positioned on a corner where there is a higher risk of impact.

Installation Steps

See the installation steps tab to view how to assemble this connector.

Antistatic Version (ESD):

An electric conductivity version if offered if you wish to build antistatic structures: HJ-3NP

Want to reuse parts of your old system?

The HJ-3 Flexpipe joint set is compatible with many other pipe and connector systems. Check the technical information tab to know which systems are compatible and none-compatible with our parts.

Please note that nuts and bolts are included, but packaged separately. Assembly is required.

| Length | 5 1/4 in (133 mm) |

|---|---|

| Height | 1 5/16 in (33 mm) |

| Width | 1 5/16 in (33 mm) |

| Material Thickness | 1/8 in (2.5 mm) |

| Weight (kg/lbs) | 0.706 lb (0.321 kg) |

| Compatible brand | Creform, NIS, C Tek Lean Solutions, Trilogiq (28 mm) |

| Non Compatible Brand | Fastube, Trilogiq (28.6 mm) |

| Primary Material | Hot rolled steel (SPHC) with black cathodic electrodeposition (Ecoating) |

| Temperature Resistance | -148°F to 572°F (-100°C to 300°C) |

| Electric Conductivity (ESD) | No |

| Manufacturing Technique | Stamping and deburring |

- Ensure you have the following parts:

- Fix an H-2 connector in the inner corner with an H-4 and loosely tighten around the first pipe using an M6-25B with an M6-N in the corresponding openings.

- Repeat with the remaining H-2 and fix to the connectors already in place, and loosely tighten the remaining M6-25B and M6-N in the corresponding openings.

- Insert the second, third and fourth pipe within the openings of the HJ-3, and between the first and the second positioning guidelines.

- Tighten the M6-25B and the M6-N until the HJ-3 is firmly attached to the four pipes.

You need to enter info before adding a new review.

Need more informations ?

Here's everything you need to know!

English US

English US English CA

English CA Français CA

Français CA Español US

Español US